A fundamental part of business success is improving productivity – increase your output without changing the level of input. Most of today’s increased productivity can be attributed to modern technology.

One innovation that has seen industries in automotive, mining and marine improve their productivity is the automatic parts cleaning machine. The job of cleaning machine parts was once highly labour-intensive but now it can be completed in a fraction of the time, and with fewer people. That’s improved productivity.

Keep reading as we outline how affordable parts cleaning machines are to own or rent and the top 7 reasons your business should be automating all parts cleaning.

Why You Should Use A Parts Cleaning Machine

Whether you choose to rent or buy a parts cleaning machine, you’ll notice the cost-saving benefits instantly. If you choose the right supplier, you can get a cleaning machine installed with NO CAPITAL OUTLAY. Renting also allows you to upgrade to a bigger unit as your business expands. That’s just one benefit, let’s look at the top 7 reasons why you should invest in a parts cleaning machine.

1. Reduced Costs

Introducing an automated parts washer allows businesses to cut down on labour costs. That’s an enormous saving, and not just for wages but also the time spent sourcing and training new staff. Anyone involved in HR can tell you how costly the hiring process can be.

2. Increased Productivity

As mentioned in the intro, a parts cleaning machine instantly increases productivity. If you compare the amount of time it would take to clean parts by hand versus using an automatic parts cleaner, well, there is no comparison. Not only can you clean more parts per day, you’ll also free up workers to help in other areas of your business.

3. Improved Quality of Cleaning

The combination of the machine’s spinning motion, high water pressure and specially formulated cleaning agent produces a far greater clean than any manual hand cleaning could. Once the cleaning process is complete, your parts will be completely free of carbon, oil and grease.

4. Better Protection for Parts

Using an alkaline salt based chemical detergent means that each part can receive a thorough industrial clean without any damage to the metal or stainless steel. In addition to this, a rust inhibitor is used to add a protective coating that will prevent your parts from rusting.

5. Enhanced Health and Safety

The specially formulated detergent removes any need to use hazardous cleaning solvents (commonly used when hand washing parts). Also, all machine parts are cleaned in an enclosed area meaning your employees are not exposed to dangerous chemicals or fumes.

6. Create Higher Skilled Employees

The job of hand cleaning machine parts is long and tedious work. Using an automated machine to do the cleaning frees up your employees to perform more productive and satisfying work.

7. Reduce Carbon Footprint

All businesses must find ways to reduce their impact on the environment. Using an automatic parts washer eliminates the use of dangerous hydrocarbon-based solvents. This is important during the cleaning process and when disposing of wastewater.

How to Choose A Parts Cleaning Machine Supplier

If you’re in charge of servicing automotive, machinery or mining equipment, an automatic parts cleaner is a vital piece of equipment. Whether you have small machine parts that require precise cleaning or large heavy industrial parts like an engine block, a quality parts cleaner will remove grease, dirt and grime without fail.

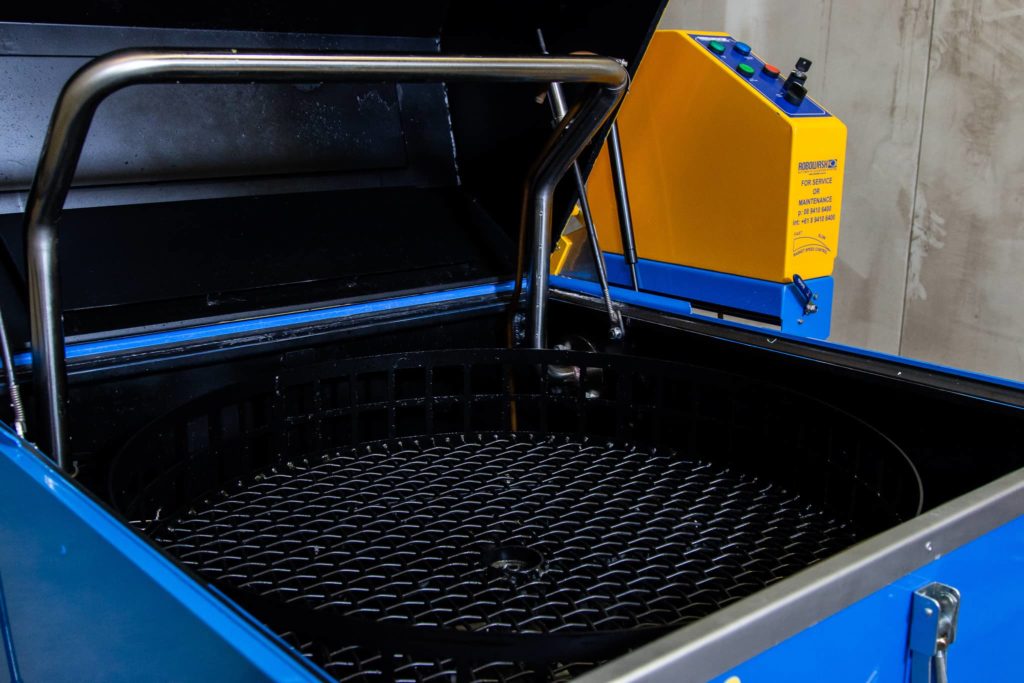

Now that you’re set on improving productivity, it’s time to choose a supplier. Perth based Robowash is one of the world’s leading manufacturers and suppliers of automatic cleaning systems and services companies around the globe. Robowash can deliver a customised, cost-effective solution to ensure you get the right sized machine for your business. From 3D modelling of the cleaning process to installation, training and ongoing maintenance, Robowash offers a complete service.

To find out more contact the team at Robowash.